About Company

Sigri New Material Technology(Tianjin) Co., Ltd, is the only designated distributor of Kaifeng Pingmei New Carbon Material Technology Co., Ltd., mainly exporting graphite electrode series products, Kaifeng Pingmei New Carbon Material Technology Co., Ltd provide the quality assurance and after-sales service for all these graphite electrodes products.

Kaifeng Pingmei New Carbon Materials Technology Co., Ltd., situated in Kaifeng, the ancient capital of eight dynasties, has a complete carbon industry chain. KFCC has formed a diverse and integrated development pattern in the graphite electrode industry and related industries. It is a modern high-tech enterprise with world-class technology equipment and internationally topnotch product quality.

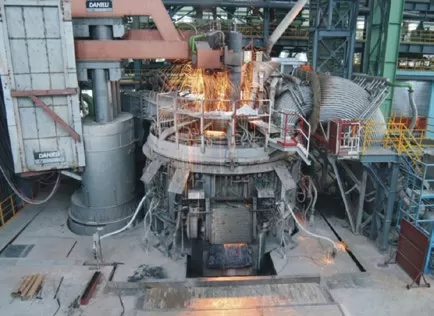

KFCC annually produces 100,000 tons of graphite electrodes ranging from Φ400 to Φ800mm,covering ultra-high power, high power, and ordinary power graphite electrodes, widely used for steelmaking in electric arc furnace and smelting in ore smelting furnaces. The company holds a leading position in the domestic field of large-sized ultra high power graphite electrodes and is the only carbon production enterprise worldwide with a complete industry chain. Its core product, the large-sized ultra high power graphite electrode, is popular among more than 30 countries and regions and over 60 end-users.The Φ800mm ultralarge-sized, ultra high power graphite electrode fills the gap in the domestic carbon industry.

KFCC consistently reinforces innovation-driven development, pushes the industrial system to maintain a medium to high end level, promotes cooperative development in production,study, research, and application, and strives to become a top-tier domestic and world-famous green carbon enterprise.

Quality Control

Quality inspection and assurance

There is pursuit of excellence behind the production of each graphite electrode. They devote themselves to every step of production and strictly control the quali- ty. KFCC possesses an integrated system for supervi- sion, inspection, and quality assurance from raw mate- rials, semi-finished to finished products. KFCC is in line with international standards in production manage- ment, quality control, production safety, technology development, occupational health, product sales, logistic statistics and customer service.

Sales & Service

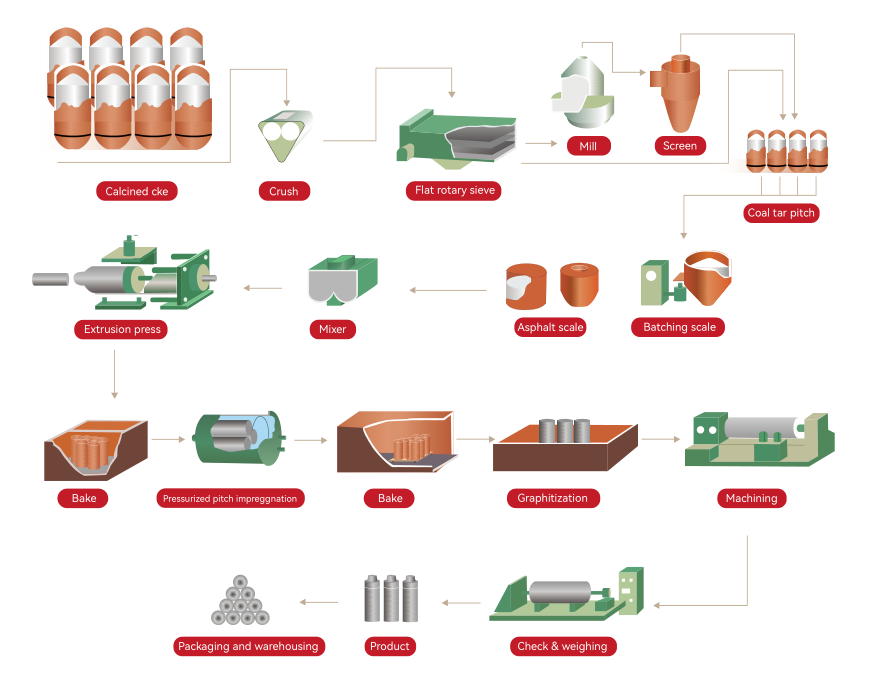

PRODUCTION FLOW CHART

In a large tank, the raw material, calcined needle coke, is broken, screened, and milled into particles of various sizes. After weighing and batching, they are mixed and extruded for molding with a certain amount of coal tar pitch. The molded green electrodes goes through the processes of baking, impregnation, and another round of baking. The semi-finished

electrode after baking is further processed through graphitization and machining to pro- duce finished graphite electrodes. These electrodes are inspected, weighed, pre-assembled,and finally packaged to be stored.

Pre-sale service:

Before sales service

Discussion with steel plants to get specific requirement of electrode and on-site measurement and supervision on electrode connection before using.

In sales service

Discussion and evaluation on electrode performance with steel mill technicians.

After-sales service:

Regular customer visit to get specific performance results and listen to feedback and suggestion from steel mills. Improve product quality continuously to meet customer's requirement.

Quality Tracking: Timely handle quality issues put forward by customer. Arrive domestic mills within 24 hours to solve quality problems and dispatch technicians to plants to find out reasons for the problem and continuously improve product quality

Regular customer visit to get specific performance results and listen to feedback and suggestion from steel mills. Improve product quality continuously to meet customer's requirement.

FACTORY & WORKSHOP

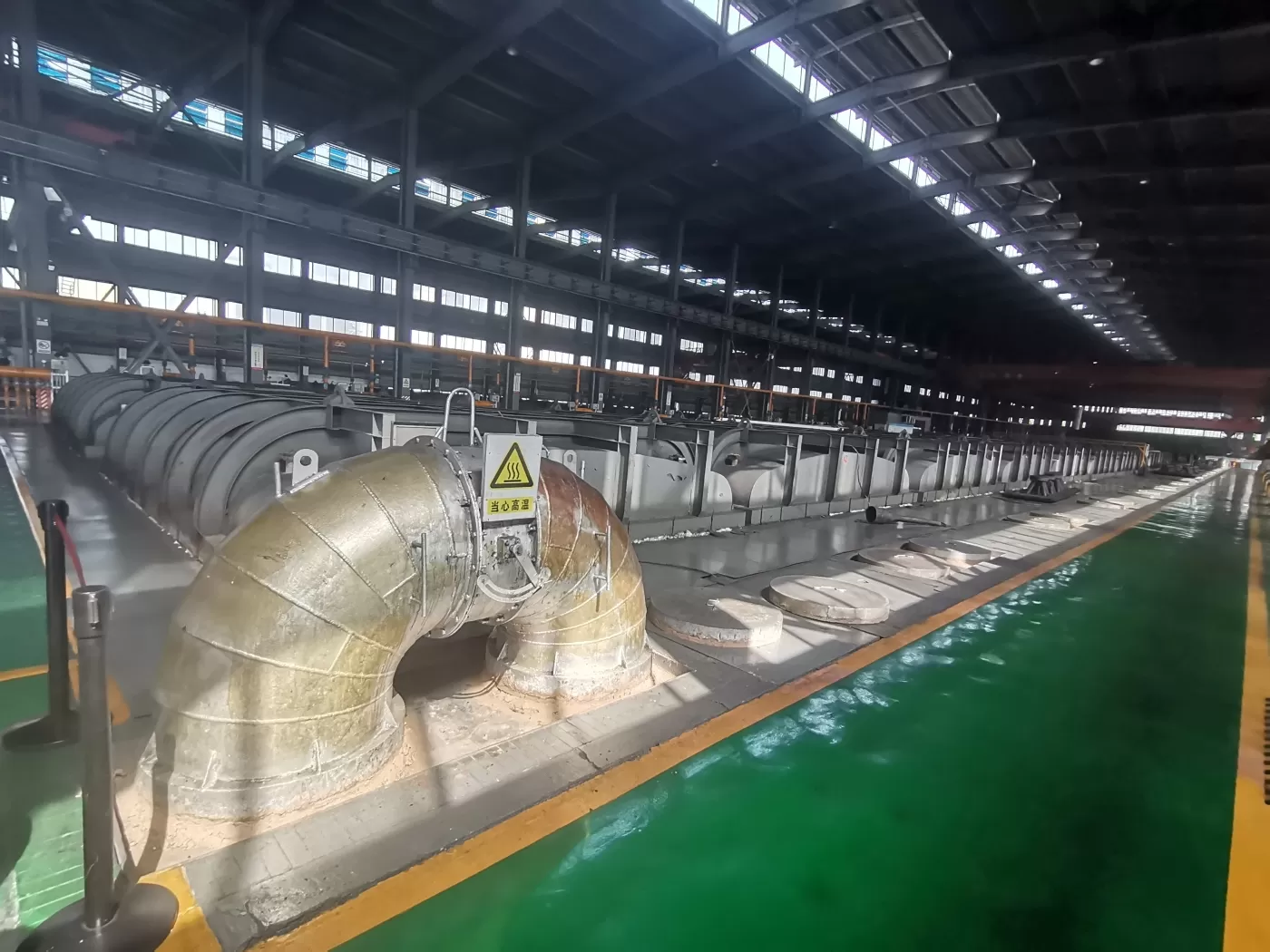

01_PRODUCTION FACILITY

KFCC possesses a complete proven process technology for manufacturing UHP graphite elec-trode and has been integrated with internationally advanced process equipment. The Mill/Mix/Ex-trusion contains all foreign sourced equipment such as screen, mill, auto batch, 3-unit mixingsystem and extrusion press. Bake area is equipped with foreign car bottom furnaces and pitchimpregnation system. Advanced LWG process technology was adopted for graphitization andmachining area is equipped with foreign CNC electrode machining line and domestically manu-factured nipple machining line.All the production facilities are controlled by PLC.

02_PRODUCTION FACILITY

KFCC possesses a complete proven process technology for manufacturing UHP graphite elec-trode and has been integrated with internationally advanced process equipment. The Mill/Mix/Ex-trusion contains all foreign sourced equipment such as screen, mill, auto batch, 3-unit mixingsystem and extrusion press. Bake area is equipped with foreign car bottom furnaces and pitchimpregnation system. Advanced LWG process technology was adopted for graphitization andmachining area is equipped with foreign CNC electrode machining line and domestically manu-factured nipple machining line.All the production facilities are controlled by PLC.

03_PRODUCTION FACILITY

KFCC possesses a complete proven process technology for manufacturing UHP graphite elec-trode and has been integrated with internationally advanced process equipment. The Mill/Mix/Ex-trusion contains all foreign sourced equipment such as screen, mill, auto batch, 3-unit mixingsystem and extrusion press. Bake area is equipped with foreign car bottom furnaces and pitchimpregnation system. Advanced LWG process technology was adopted for graphitization andmachining area is equipped with foreign CNC electrode machining line and domestically manu-factured nipple machining line.All the production facilities are controlled by PLC.

04_PRODUCTION FACILITY

KFCC possesses a complete proven process technology for manufacturing UHP graphite elec-trode and has been integrated with internationally advanced process equipment. The Mill/Mix/Ex-trusion contains all foreign sourced equipment such as screen, mill, auto batch, 3-unit mixingsystem and extrusion press. Bake area is equipped with foreign car bottom furnaces and pitchimpregnation system. Advanced LWG process technology was adopted for graphitization andmachining area is equipped with foreign CNC electrode machining line and domestically manu-factured nipple machining line.All the production facilities are controlled by PLC.

05_PRODUCTION FACILITY

KFCC possesses a complete proven process technology for manufacturing UHP graphite elec-trode and has been integrated with internationally advanced process equipment. The Mill/Mix/Ex-trusion contains all foreign sourced equipment such as screen, mill, auto batch, 3-unit mixingsystem and extrusion press. Bake area is equipped with foreign car bottom furnaces and pitchimpregnation system. Advanced LWG process technology was adopted for graphitization andmachining area is equipped with foreign CNC electrode machining line and domestically manu-factured nipple machining line.All the production facilities are controlled by PLC.

06_PRODUCTION FACILITY

KFCC possesses a complete proven process technology for manufacturing UHP graphite elec-trode and has been integrated with internationally advanced process equipment. The Mill/Mix/Ex-trusion contains all foreign sourced equipment such as screen, mill, auto batch, 3-unit mixingsystem and extrusion press. Bake area is equipped with foreign car bottom furnaces and pitchimpregnation system. Advanced LWG process technology was adopted for graphitization andmachining area is equipped with foreign CNC electrode machining line and domestically manu-factured nipple machining line.All the production facilities are controlled by PLC.

07_PRODUCTION FACILITY

KFCC possesses a complete proven process technology for manufacturing UHP graphite elec-trode and has been integrated with internationally advanced process equipment. The Mill/Mix/Ex-trusion contains all foreign sourced equipment such as screen, mill, auto batch, 3-unit mixingsystem and extrusion press. Bake area is equipped with foreign car bottom furnaces and pitchimpregnation system. Advanced LWG process technology was adopted for graphitization andmachining area is equipped with foreign CNC electrode machining line and domestically manu-factured nipple machining line.All the production facilities are controlled by PLC.

08_PRODUCTION FACILITY

KFCC possesses a complete proven process technology for manufacturing UHP graphite elec-trode and has been integrated with internationally advanced process equipment. The Mill/Mix/Ex-trusion contains all foreign sourced equipment such as screen, mill, auto batch, 3-unit mixingsystem and extrusion press. Bake area is equipped with foreign car bottom furnaces and pitchimpregnation system. Advanced LWG process technology was adopted for graphitization andmachining area is equipped with foreign CNC electrode machining line and domestically manu-factured nipple machining line.All the production facilities are controlled by PLC.

09_PRODUCTION FACILITY

KFCC possesses a complete proven process technology for manufacturing UHP graphite elec-trode and has been integrated with internationally advanced process equipment. The Mill/Mix/Ex-trusion contains all foreign sourced equipment such as screen, mill, auto batch, 3-unit mixingsystem and extrusion press. Bake area is equipped with foreign car bottom furnaces and pitchimpregnation system. Advanced LWG process technology was adopted for graphitization andmachining area is equipped with foreign CNC electrode machining line and domestically manu-factured nipple machining line.All the production facilities are controlled by PLC.

Exporting Countries

KFCC has license for import and export. By the end of 2022, our products have been sold in more than 30 countries and regions, including Canada, Mexico, the United Kingdom, Spain, India, Thai- land, Singapore, Korea and Japan.